Barra de aço inoxidável

Descrição do produto

Tipo: Aço Inoxidável Grau de aço: Série 200 Aplicação: Barra de aço estrutural, barra de aço da ferramenta, Die Liga de barra de aço: Não-liga Material: Ss201 / 202/301/304/316 / 309S / 310/321/410/420/430 Seção: Redondo, Hexagonal, Quadrado Especificação: 0.5-500mm Padrão: AISI, ASTM, GB, JIS, DIN, BS Técnica: Tratamento de superfície Drenado a frio: Polido Uso especial: Aço de corte livre Padrões: ASTM, AISI, DIN, En, GB , JIS Trademark: DERBOSTEEL Origem: Wenzhou

Informação básica:

Inspeção do Partido Thrid:

A inspeção de terceiros que é preferida por novos clientes é provada ser convincente. Através de anos de operação, M / S Chengdu Derbo estabeleceu contato estável com as autoridades de fiscalização de terceiros famosos como BV, SGS, INTERTEK, etc, e mais de 5000M.Tons de chapa de aço de Chengdu Derbo foram inspeccionados por eles.

Por favor, não hesite em contactar-me se você tem alguma queires em nossos produtos!

Ofereceremos nosso serviço caloroso a você!

Informação básica:

|

Description |

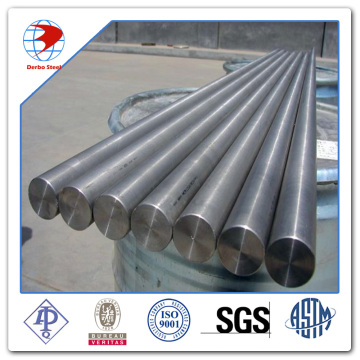

stainless steel round bar |

|

|

Standard |

ASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311, DIN 1654-5,DIN 17440 |

|

|

Material |

303, 304,304L,309S,310S,316,316L,316Ti,317,317L,321,347H, 201,202,410,420,430,etc |

|

|

Type |

Round, square, hexagonal, flat, angle |

|

|

Surface |

Pickled, Black, right, Polishing, Blasting, etc |

|

|

Specifications |

Round bar |

Diameter: 3mm~800mm |

|

Angle bar |

Size: 3mm*20mm*20mm~12mm*100mm*100mm |

|

|

Square bar |

Size: 4mm*4mm~100mm*100mm |

|

|

Flat bar |

Thickness: 2mm~100mm |

|

|

Width: 10mm~500mm | ||

|

Hexagonal |

Size: 2mm~100mm |

|

|

Length |

6m,5.8m,12m or as required |

|

|

Price Term |

EX-Work, FOB, CFR, CIF,CNF |

|

|

Payment Term |

T/T,L/C |

|

|

Market |

Europe, South America, Africa ,Oceania ,canada, Australia,such as : USA, Germany, India, Iran, Dubai, Iraq, Vietnam, Ireland,Singapore, etc. |

|

|

Package |

Bundled, wooden box, export standard package. |

|

|

Delivery Time |

Normally according to the order quantity |

|

|

Application |

chemical industry, shipping industry, manufacturing industry, construction, decorate Industry, electric power, pump shafts, sanitary wares ,furniture handles,boiler, high temperature resistant, low temperature resistant, corrosion resistant. |

|

| Chemical Requirements ASTM A276-06 | ||||||||||

| UNS | Type | Composition, % | ||||||||

| Designa- tionB | Phos- phorus | Molyb- denum | ||||||||

| Carbon | Manganese | Sulfur | Silicon | Chromium | Nickel | Nitrogen | ||||

| Austenitic Grades | ||||||||||

| S20100 | 201 | 0.15 | 5.5-7.5 | 0.06 | 0.03 | 1 | 16.0-18.0 | 3.5-5.5 | . . . | 0.25 |

| S20161 | . . . | 0.15 | 4.0-6.0 | 0.045 | 0.03 | 3.0-4.0 | 15.0-18.0 | 4.0-6.0 | . . . | 0.08-0.20 |

| S20162 | . . . | 0.15 | 4.0-8.0 | 0.04 | 0.04 | 2.5-4.5 | 16.5-21.0 | 6.0-10.0 | 0.50-2.50 | 0.05-0.25 |

| S20200 | 202 | 0.15 | 7.5-10.0 | 0.06 | 0.03 | 1 | 17.0-19.0 | 4.0-6.0 | . . . | 0.25 |

| S20500 | 205 | 0.12-0.25 | 14.0-15.5 | 0.06 | 0.03 | 1 | 16.5-18.0 | 1.0-1.7 | . . . | 0.32-0.40 |

| S20910 | XM-19 | 0.06 | 4.0-6.0 | 0.045 | 0.03 | 1 | 20.5-23.5 | 11.5-13.5 | 1.50-3.00 | 0.20-0.40 |

| S21800 | . . . | 0.1 | 7.0-9.0 | 0.06 | 0.03 | 3.5-4.5 | 16.0-18.0 | 8.0-9.0 | . . . | 0.08-0.18 |

| S21900 | XM-10 | 0.08 | 8.0-10.0 | 0.045 | 0.03 | 1 | 19.0-21.5 | 5.5-7.5 | . . . | 0.15-0.40 |

| S21904 | XM-11 | 0.04 | 8.0-10.0 | 0.045 | 0.03 | 1 | 19.0-21.5 | 5.5-7.5 | . . . | 0.15-0.40 |

| S24000 | XM-29 | 0.08 | 11.5-14.5 | 0.06 | 0.03 | 1 | 17.0-19.0 | 2.3-3.7 | . . . | 0.20-0.40 |

| S24100 | XM-28 | 0.15 | 11.0-14.0 | 0.045 | 0.03 | 1 | 16.5-19.0 | 0.50-2.50 | . . . | 0.20-0.45 |

| S28200 | . . . | 0.15 | 17.0-19.0 | 0.045 | 0.03 | 1 | 17.0-19.0 | . . . | 0.75-1.25 | 0.40-0.60 |

| S30200 | 302 | 0.15 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 8.0-10.0 | . . . | 0.1 |

| S30215 | 302B | 0.15 | 2 | 0.045 | 0.03 | 2.00-3.00 | 17.0-19.0 | 8.0-10.0 | . . . | 0.1 |

| S30400 | 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | . . . | . . . |

| S30403 | 304LC | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-12.0 | . . . | . . . |

| S30451 | 304N | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | . . . | 0.10-0.16 |

| S30452 | XM-21 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-10.0 | . . . | 0.16-0.30 |

| S30453 | 304LN | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | . . . | 0.10-0.16 |

| S30454 | . . . | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | . . . | 0.16-0.30 |

| S30500 | 305 | 0.12 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 11.0-13.0 | . . . | . . . |

| S30800 | 308 | 0.08 | 2 | 0.045 | 0.03 | 1 | 19.0-21.0 | 10.0-12.0 | . . . | . . . |

| S30815 | . . . | 0.05-0.10 | 0.8 | 0.04 | 0.03 | 1.40-2.00 | 20.0-22.0 | 10.0-12.0 | . . . | 0.14-0.20 |

| S30900 | 309 | 0.2 | 2 | 0.045 | 0.03 | 1 | 22.0-24.0 | 12.0-15.0 | . . . | . . . |

| S30908 | 309S | 0.08 | 2 | 0.045 | 0.03 | 1 | 22.0-24.0 | 12.0-15.0 | . . . | . . . |

| S30940 | 309Cb | 0.08 | 2 | 0.045 | 0.03 | 1 | 22.0-24.0 | 12.0-16.0 | . . . | . . . |

| S31000 | 310 | 0.25 | 2 | 0.045 | 0.03 | 1.5 | 24.0-26.0 | 19.0-22.0 | . . . | . . . |

| S31008 | 310S | 0.08 | 2 | 0.045 | 0.03 | 1.5 | 24.0-26.0 | 19.0-22.0 | . . . | . . . |

| S31040 | 310Cb | 0.08 | 2 | 0.045 | 0.03 | 1.5 | 24.0-26.0 | 19.0-22.0 | . . . | . . . |

| S31254 | . . . | 0.02 | 1 | 0.03 | 0.01 | 0.8 | 19.5-20.5 | 17.5-18.5 | 6.0-6.5 | 0.18-0.22 |

| S31400 | 314 | 0.25 | 2 | 0.045 | 0.03 | 1.50-3.00 | 23.0-26.0 | 19.0-22.0 | . . . | . . . |

| S31600 | 316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | . . . |

| S31603 | 316LC | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | . . . |

| S31635 | 316Ti | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | 0.1 |

| S31640 | 316Cb | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | 0.1 |

| S31651 | 316N | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | 0.10-0.16 |

| S31653 | 316LN | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-13.0 | 2.00-3.00 | 0.10-0.16 |

| S31654 | ... | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-13.0 | 2.00-3.00 | 0.16-0.30 |

| S31700 | 317 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | 0.1 |

| S31725 | . . . | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 13.5-17.5 | 4.0-5.0 | 0.2 |

| S31726 | . . . | 0.03 | 2 | 0.045 | 0.03 | 1 | 17.0-20.0 | 14.5-17.5 | 4.0-5.0 | 0.10-0.20 |

| S31727 | . . . | 0.03 | 1 | 0.03 | 0.03 | 1 | 17.5-19.0 | 14.5-16.5 | 3.8-4.5 | 0.15-0.21 |

| S32053 | . . . | 0.03 | 1 | 0.03 | 0.01 | 1 | 22.0-24.0 | 24.0-26.0 | 5.0-6.0 | 0.17-0.22 |

| S32100 | 321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | . . . | . . . |

| S32654 | . . . | 0.02 | 2.0-4.0 | 0.03 | 0.005 | 0.5 | 24.0-25.0 | 21.0-23.0 | 7.0-8.0 | 0.45-0.55 |

| S34565 | . . . | 0.03 | 5.0-7.0 | 0.03 | 0.01 | 1 | 23.0-25.0 | 16.0-18.0 | 4.0-5.0 | 0.40-0.60 |

| S34700 | 347 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | . . . | . . . |

| S34800 | 348 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | . . . | . . . |

| Ferritic Grades | ||||||||||

| S40500 | 405 | 0.08 | 1 | 0.04 | 0.03 | 1 | 11.5-14.5 | 0.5 | . . . | . . . |

| S40976 | . . . | 0.03 | 1 | 0.04 | 0.03 | 1 | 10.5-11.7 | 0.75-1.00 | . . . | 0.04 |

| S42900 | 429 | 0.12 | 1 | 0.04 | 0.03 | 1 | 14.0-16.0 | . . . | . . . | . . . |

| S43000 | 430 | 0.12 | 1 | 0.04 | 0.03 | 1 | 16.0-18.0 | . . . | . . . | . . . |

| S44400 | 444 | 0.025 | 1 | 0.04 | 0.03 | 1 | 17.5-19.5 | 1 | 1.75-2.50 | 0.035 |

| S44600 | 446 | 0.2 | 1.5 | 0.04 | 0.03 | 1 | 23.0-27.0 | 0.75 | . . . | 0.25 |

| S44627 | XM-27F | 0.010G | 0.4 | 0.02 | 0.02 | 0.4 | 25.0-27.5 | 0.5 | 0.75-1.50 | 0.015G |

| S44700 | . . . | 0.01 | 0.3 | 0.025 | 0.02 | 0.2 | 28.0-30.0 | 0.15 | 3.5-4.2 | 0.02 |

| S44800 | . . . | 0.01 | 0.3 | 0.025 | 0.02 | 0.2 | 28.0-30.0 | 2.00-2.50 | 3.5-4.2 | 0.02 |

| Martensitic Grades | ||||||||||

| S40300 | 403 | 0.15 | 1 | 0.04 | 0.03 | 0.5 | 11.5-13.0 | . . . | . . . | . . . |

| S41000 | 410 | 0.08-0.15 | 1 | 0.04 | 0.03 | 1 | 11.5-13.5 | . . . | . . . | . . . |

| S41040 | XM-30 | 0.18 | 1 | 0.04 | 0.03 | 1 | 11.0-13.0 | . . . | . . . | . . . |

| S41400 | 414 | 0.15 | 1 | 0.04 | 0.03 | 1 | 11.5-13.5 | 1.25-2.50 | . . . | . . . |

| S41425 | . . . | 0.05 | 0.50-1.00 | 0.02 | 0.005 | 0.5 | 12.0-15.0 | 4.0-7.0 | 1.50-2.00 | 0.06-0.12 |

| S41500 | H | 0.05 | 0.50-1.00 | 0.03 | 0.03 | 0.6 | 11.5-14.0 | 3.5-5.5 | 0.50-1.00 | . . . |

| S42000 | 420 | 0.15 min | 1 | 0.04 | 0.03 | 1 | 12.0-14.0 | . . . | . . . | . . . |

| S42010 | . . . | 0.15-0.30 | 1 | 0.04 | 0.03 | 1 | 13.5-15.0 | 0.35-0.85 | 0.40-0.85 | . . . |

| S43100 | 431 | 0.2 | 1 | 0.04 | 0.03 | 15.0-17.0 | 1.25-2.50 | . . . | . . . | |

| S44002 | 440A | 0.60-0.75 | 1 | 0.04 | 0.03 | 1 | 16.0-18.0 | . . . | 0.75 | . . . |

| S44003 | 440B | 0.75-0.95 | 1 | 0.04 | 0.03 | 1 | 16.0-18.0 | . . . | 0.75 | . . . |

| S44004 | 440C | 0.95-1.20 | 1 | 0.04 | 0.03 | 1 | 16.0-18.0 | . . . | 0.75 | . . . |

Inspeção do Partido Thrid:

A inspeção de terceiros que é preferida por novos clientes é provada ser convincente. Através de anos de operação, M / S Chengdu Derbo estabeleceu contato estável com as autoridades de fiscalização de terceiros famosos como BV, SGS, INTERTEK, etc, e mais de 5000M.Tons de chapa de aço de Chengdu Derbo foram inspeccionados por eles.

Por favor, não hesite em contactar-me se você tem alguma queires em nossos produtos!

Ofereceremos nosso serviço caloroso a você!

Grupo de Produto : Encaixe de tubulação > Acessórios para tubos forjados e fundidos

Premium Related Products

outros produtos

produtos quentes

Tubo de aço redondo / quadrado LSAW / SSAW / ERW de qualidade superior1 / 8-20 (1 / 8-20 polegadas) de solda de aço carbono X42 ERW tubo de açoGr.B X42 X46 X52 X56 X60 API 5L tubo de aço soldado de 300 mm de diâmetroO melhor preço seção oca soldada 30 * 15 tubo de aço fabricado na ChinaTubo de água de metal espiral SSAW rodada de preço de fábrica para fluidoForneça o tubo de aço do carbono do erw para a tubulação do pólo da propagandaFornecimento de fábrica de moinhos de tubos de aço macio soldados msERW LSAW SSAW tubo de aço soldado para madeira em péTubo de aço quadrado de seção oca de alta qualidade para carrinho dollyTubo de aço laminado a frio S355JR para auto com ISO SGS CE FPCGraus Premium pintado tubo de aço preto soldado com furoAlta qualidade rodada tubo de aço de estrutura soldada exportadoresTubo de aço preto de carbono de alta qualidade em estoqueERW quadrado e tubo de aço retangular em estoqueEsquema 10/40/80 MS tubo de aço macio em estoqueDurável redondo / quadrado / retangular ferro tubo mobiliário